Ngaphandle kwalokho, omagnethi be-SmCo banezinye izici:

Ukusebenza okuthembekile: Ozibuthe be-SmCo bamelana ngokwedlulele nokukhishwa kazibuthe okubenza bathembeke ezindaweni eziningi.

Ukumelana nokugqwala kanye ne-oxidation: Ngenxa yokuqukethwe kwensimbi ephansi ezintweni eziyinhlanganisela, omagnethi be-SmCo banokumelana nokugqwala okuhle kakhulu.Ngokungafani ne-NdFeB, omagnethi be-SmCo abadingi i-electroplating.

Ukuqina kwezinga lokushisa: I-SmCo ingagcina amandla ayo kazibuthe emazingeni okushisa aphezulu (249-300 ℃) namazinga okushisa aphansi kakhulu (-232 ℃).

Izinto zokwakha ezinqamukayo: Lapho i-sintering, impahla ingase ibe brittle, ngenxa yokuthi i-brittle futhi kulula ukuqhekeka, ukucubungula kunemikhawulo, lapho izindlela zokucubungula zendabuko zingasebenzi.Noma kunjalo, ingagaywa, kodwa kuphela uma kusetshenziswa inani elikhulu lokupholisa.Lokho kungenxa yokuthi okokupholisa kunganciphisa ingozi yomlilo kusukela ekuqhekekeni okushisayo nothuli olugaywe nge-oxidized.

Izicelo:

1. Izinjini ze-PM ezisezingeni eliphezulu.Amamotho ajwayelekile e-PM ajwayele ukusebenzisa omazibuthe be-ferrite noma omagnet be-NdFeB.Kodwa ezindaweni lapho izinga lokushisa lidlula ama-200 ℃ noma i-torque enkulu, ama-motor e-SmCo PM kuphela anekhono.

2. Imishini ye-Electroacoustic kumasistimu wesipikha esikhuluma phezulu.

3. Uhlelo lwensimbi oluthembeke kakhulu.Izinsimbi eziningi ezisetshenziswa ku-aerospace, izindiza, ezokwelashwa neminye imikhakha kumele zisebenzise omazibuthe abangapheli be-SmCo ukuze kuqinisekiswe ukwethembeka okuphezulu nokuphepha okuphelele.

4. Ezinhlelweni ze-radar nezokuxhumana ezibaluleke kakhulu, kusetshenziswa inani elikhulu lamashubhu amagagasi ahambayo, omagnetron, amashubhu ajahayo, amashubhu ajaha amagagasi, ama-gyrotron namanye amadivaysi kagesi evacuum asetshenziswa, kanti omazibuthe be-SmCo benza imishayo yama-electron ekuhambeni ngendlela enqunyiwe.

5. I-SmCo extractors kazibuthe emithonjeni ejulile engaphansi kwamamitha angu-3000, kanye ne-SmCo magnetic drive (ipompo) endaweni yokushisa ephezulu engu-200 ℃.

6. Ikhanda lokumunca kazibuthe, isihlukanisi kazibuthe, i-magnetic bearing, i-NMR, njll.

SmCo Magnet Grade Uhlu

| Okubalulekile | No | Br | Hcb | Hcj | (BH) ubuningi | TC | TW | (Br) | Hcj | ||||

| T | |KGs | KA/m | KOE | KA/m | KOE | KJ/m3 | MGOe | ℃ | ℃ | %℃ | %℃ | ||

| 1:5 SmCo5 (Smpr)Co5 | YX-16 | 0.81-0.85 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.050 | -0.30 |

| YX-18 | 0.85-0.90 | 8.5-9.0 | 660-700 | 8.3-88 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.050 | -0.30 | |

| YX-20 | 0.90-0.d4 | 9.0-9.4 | 676-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.050 | -0.30 | |

| YX-22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-94 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.050 | -0.30 | |

| YX-24 | 0.96-1.00 | 9.6-10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.050 | -0.30 | |

| 1:5 SmCo5 | I-YX-16S | 0.79-0.84 | 7.9-8.4 | 612-660 | 7.7-83 | ≥ 1830 | ≥ 23 | 118-135 | 15-17 | 750 | 250 | -0.035 | -0.28 |

| I-YX-18S | 0.84-0.89 | 8.4-89 | 644-692 | 8.1-8.7 | ≥ 1830 | ≥ 23 | 135-151 | 17-19 | 750 | 250 | -0.040 | -0.28 | |

| YX-20S | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-92 | ≥ 1830 | ≥ 23 | 150-167 | 19-21 | 750 | 250 | -0.045 | -0.28 | |

| I-YX-22S | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-95 | ≥ 1830 | ≥ 23 | 167-183 | 21-23 | 750 | 250 | -0.045 | -0.28 | |

| I-YX-24S | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥ 1830 | ≥ 23 | 183-199 | 23-25 | 750 | 250 | -0.045 | -0.28 | |

| 1:5 (SmGd)Co5 | I-LTc(YX-10) | 0.62-0.66 | 62-6.6 | 485-517 | 6.1-6.5 | ≥ 1830 | ≥ 23 | 75-8A | 9.5-11 | 750 | 300 | 20-100℃ +0.0156%℃ 100-200 ℃ +0.0087%℃ 200-300 ℃ +0.0007%℃ | |

| I-Ce(CoFeCu)5 | YX-12 | 0.7Q-0.74 | 7.0-7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

| Sm2 (CoFeCuZr)17 | YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥ 1990 | ≥ 25 | 175-191 | 22-24 | 800 | 350 | -0.025 | -0.20 |

| YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1990 | ≥ 25 | 191-207 | 24-26 | 800 | 350 | -0.030 | -0.20 | |

| YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1990 | ≥ 25 | 207-220 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

| YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1990 | ≥ 25 | 220-240 | 28-30 | 800 | 350 | -0.035 | -0.20 | |

| I-YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1990 | ≥ 25 | 230-255 | 29-32 | 800 | 350 | -0.035 | -0.20 | |

| YXG-22 | 0.93-0.97 | 9.3-97 | 676-740 | 8.5-93 | ≥ 1453 | ≥ 18 | 160-183 | 20-23 | 800 | 300 | -0.020 | -0.20 | |

| YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 87-9.6 | ≥ 1433 | ≥ 18 | 175-191 | 22-24 | 800 | 300 | -0.025 | -0.20 | |

| YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1433 | ≥ 18 | 191-207 | 24-26 | 800 | 300 | -0.030 | -0.20 | |

| YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1433 | ≥ 18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1453 | ≥ 18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1433 | ≥ 18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.20 | |

| YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| I-YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | 800 | 250 | -0.025 | -0.20 | |

| YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | 800 | 250 | -0.035 | -0.20 | |

| YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.20 | |

| YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.20 | |

| I-YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.20 | |

| (SmEr)2(CoTM)17 | I-LTC (YXG-22) | 0.94-0,98 | 9.4-9.8 | 668-716 | 8.4-9.0 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | -50-25℃ +0.005%℃ 20-100℃ -0.008%℃ 100-200 ℃ -0.008%℃ 200-300℃ -0.011%℃ | |

| Izakhiwo ezingokomzimba zeSamarium Cobalt | ||

| Ipharamitha | SmKo 1:5 | SmKo 2:17 |

| Izinga lokushisa le-Curie(℃) | 750 | 800 |

| Izinga lokushisa eliphezulu lokusebenza(℃ | 250 | 300 |

| I-Hv(MPa) | 450-500 | 550-600 |

| Ukuminyana(g/cm³) | 8.3 | 8.4 |

| I-coefficient yezinga lokushisa le-Br(%/℃) | -0.05 | -0.035 |

| I-coefficient yezinga lokushisa ye-iHc(%/℃) | -0.3 | -0.2 |

| Amandla okuqina (N/mm) | 400 | 350 |

| Amandla okuphuka aguquguqukayo (N/mm) | 150-180 | 130-150 |

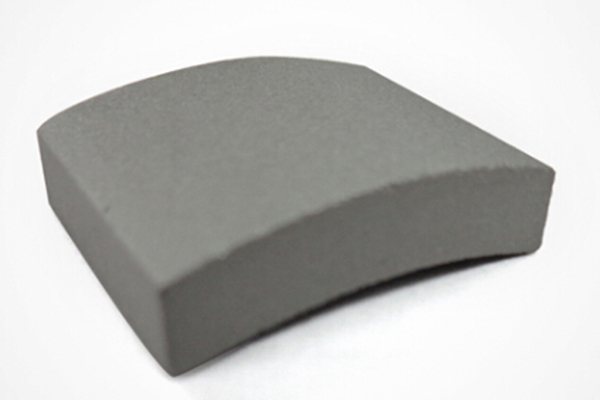

Isicelo

I-SmCo uzibuthe isetshenziswa kabanzi ku-aerospace, motor ukumelana nokushisa okuphezulu, imishini ye-microwave, ukuxhumana, imishini yezokwelapha, izinsimbi namamitha, imishini yokudlulisa kazibuthe ehlukahlukene, izinzwa, amaprosesa kazibuthe, ama-coil motors wezwi nokunye.

Isibonisi Sesithombe

-

Ingxenye ye-NdFeB, ngokuvamile isetshenziswa kugesi ...

-

Round NdFeb, ngokuvamile isetshenziswa electroacou...

-

Osayizi abahlukene bezibuthe zenjoloba/ ishidi likakazibuthe

-

Ezinye Izimo NdFeB, ezifana nokuma kwesinkwa, imigodi...

-

Ring NdFeB, ngokuvamile esetshenziselwa isipikha

-

I-Magnet Assemblies ene-NdFeB, SmCo, AlNiCo kanye ...