Sisebenzisa ifomula ye-no-dysprosium emikhiqizweni yezinga eliphansi ukuze amakhasimende ehlise izindleko.Sinefomula ezinzile engenziwa imikhiqizo ye-coefficient yezinga lokushisa eliphansi.Yehlisa izindleko futhi ikhulise ukusebenza kahle kumakhasimende ngokulawula ngokuqinile ukubekezelelana ekucubunguleni kanye nokwemboza ngokwezidingo ezahlukahlukene zamakhasimende ukuze kuqinisekiswe ukuzinza kokuvikelwa kwe-plating ngasikhathi sinye, kufaka phakathi isifutho sikasawoti, amandla okubopha, ukuhlangana kwe-colloid nokunye. .

Imikhiqizo eyindilinga ijwayele ukushoda enqubweni yokukhiqiza.Ngakho-ke sinemishini yokuhlola egcwele ezenzakalelayo yokubekezelela ukubukeka, engaqinisekisa ukonakala komkhiqizo ngaphakathi kwebanga elilawulekayo futhi igweme imikhiqizo enesici ekusebenziseni inqubo.

Ngokuvumelana nokuguquguquka kwe-flux, siqinisekisa ukuthi isithando somlilo esingaguquki sifinyelela ukuvumelana kokulawulwa kwenqubo kazibuthe, kanye nemishini yokuhlola egeleza kazibuthe egcwele ukuvimbela imikhiqizo kazibuthe ebuthaka ukuthi ingagelezi iye kumakhasimende.Ngokuphathelene nokupakisha kazibuthe, inkampani yethu inomkhondo wemishini kazibuthe yokufaka ikhodi ukuze ivikele abasebenzi ekushajeni imali kazibuthe.

Mayelana nokulawulwa kokulethwa, inani elikhulu lemishini yokusika enemigqa eminingi, amayunithi okusika, abasebenzi abavuthiwe bezobuchwepheshe, ukuqapha inqubo yomkhiqizo ophelele, isinyathelo ngasinye sokucubungula nokukhiqiza umkhiqizo singathola impendulo yenqubekelaphambili nganoma yisiphi isikhathi, umugqa ovuthiwe wokukhiqiza umkhiqizo oyi-cylindrical, ukuqinisekisa izimfuneko zokulawula amakhasimende zokulethwa komkhiqizo, kanye nenqubekelaphambili yokukhiqiza elawulekayo.

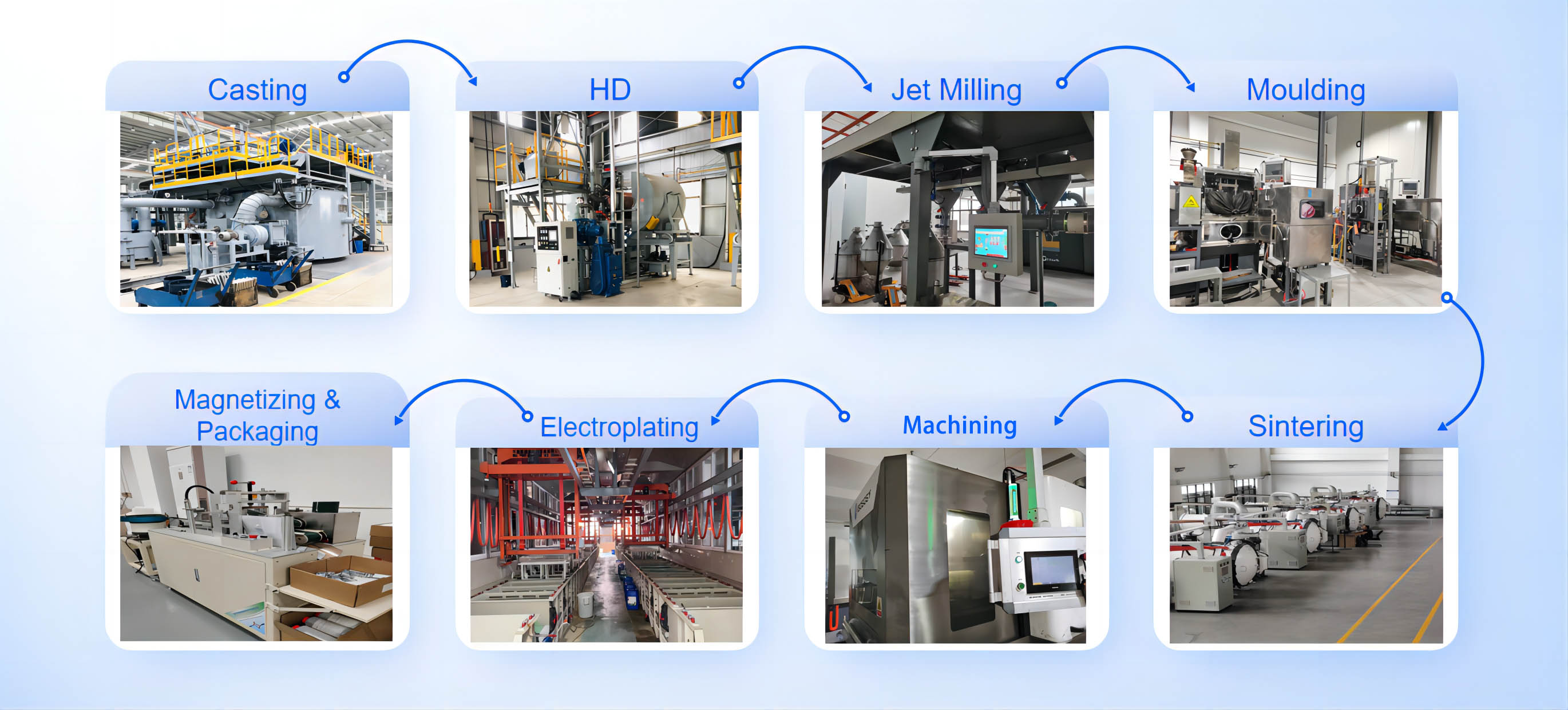

Inqubo Yokukhiqiza ye-NdFeB

Isingeniso sokumboza

| Ubuso | Ukugqoka | Ubukhulu μm | Umbala | Amahora we-SST | Amahora we-PCT | |

| I-Nickel | Ni | 10 - 20 | Isiliva Elikhanyayo | > 24-72 | > 24-72 | |

| Ni+Cu+Ni | ||||||

| I-Nickel Emnyama | Ni+Cu+Ni | 10 - 20 | Okumnyama Okukhanyayo | > 48-96 | >48 | |

| I-Cr3+Zinc | Zn C-Zn | 5; 8 | UBrighe Blue Umbala Ocwebezelayo | > 16-48 > 36-72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 - 25 | Isiliva | > 36-72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10 - 15 | Igolide | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10; 15 | Isiliva | >12 | >48 | |

| I-Epoxy | I-Epoxy | 10 - 20 | Mnyama/Mpunga | >48 | --- | |

| Ni+Cu+Epoxy | 15 - 30 | > 72-108 | --- | |||

| I-Zn+Epoxy | 15 - 25 | > 72-108 | --- | |||

| Passivation | --- | 1; 3 | Okumpunga Okumnyama | Ukuvikelwa Kwesikhashana | --- | |

| I-Phosphate | --- | 1; 3 | Okumpunga Okumnyama | Ukuvikelwa Kwesikhashana) | --- | |

Izici Zomzimba

| Into | Amapharamitha | Inani Lereferensi | Iyunithi |

| I-Axiliary Magnetic Izakhiwo | I-Reversible Temperature Coefficient Ye-Br | -0.08--0.12 | %/℃ |

| I-Reversible Temperature Coefficient Of Hcj | -0.42-0.70 | %/℃ | |

| Ukushisa Okuthize | 0.502 | KJ ·(Kg ·℃)-1 | |

| I-Curie Temperature | 310~380 | ℃ | |

| Mechanical Physical Izakhiwo | Ukuminyana | 7.5~7.80 | g/cm3 |

| Vickers Ukuqina | 650 | Hv | |

| Ukumelana Nogesi | 1.4x10-6 | μQ ·m | |

| Amandla Acindezelayo | 1050 | I-MPa | |

| Amandla Okuqina | 80 | Mpa | |

| Ukugoba Amandla | 290 | Mpa | |

| I-Thermal Conductivity | 6 - 8.95 | W/m ·K | |

| I-Modulus Encane | 160 | I-GPa | |

| I-Thermal Expansion(C⊥) | -1.5 | 10-6/℃-1 | |

| I-Thermal Expansion(CII) | 6.5 | 10-6/℃-1 |

Isibonisi Sesithombe